Sussex Scrimmage

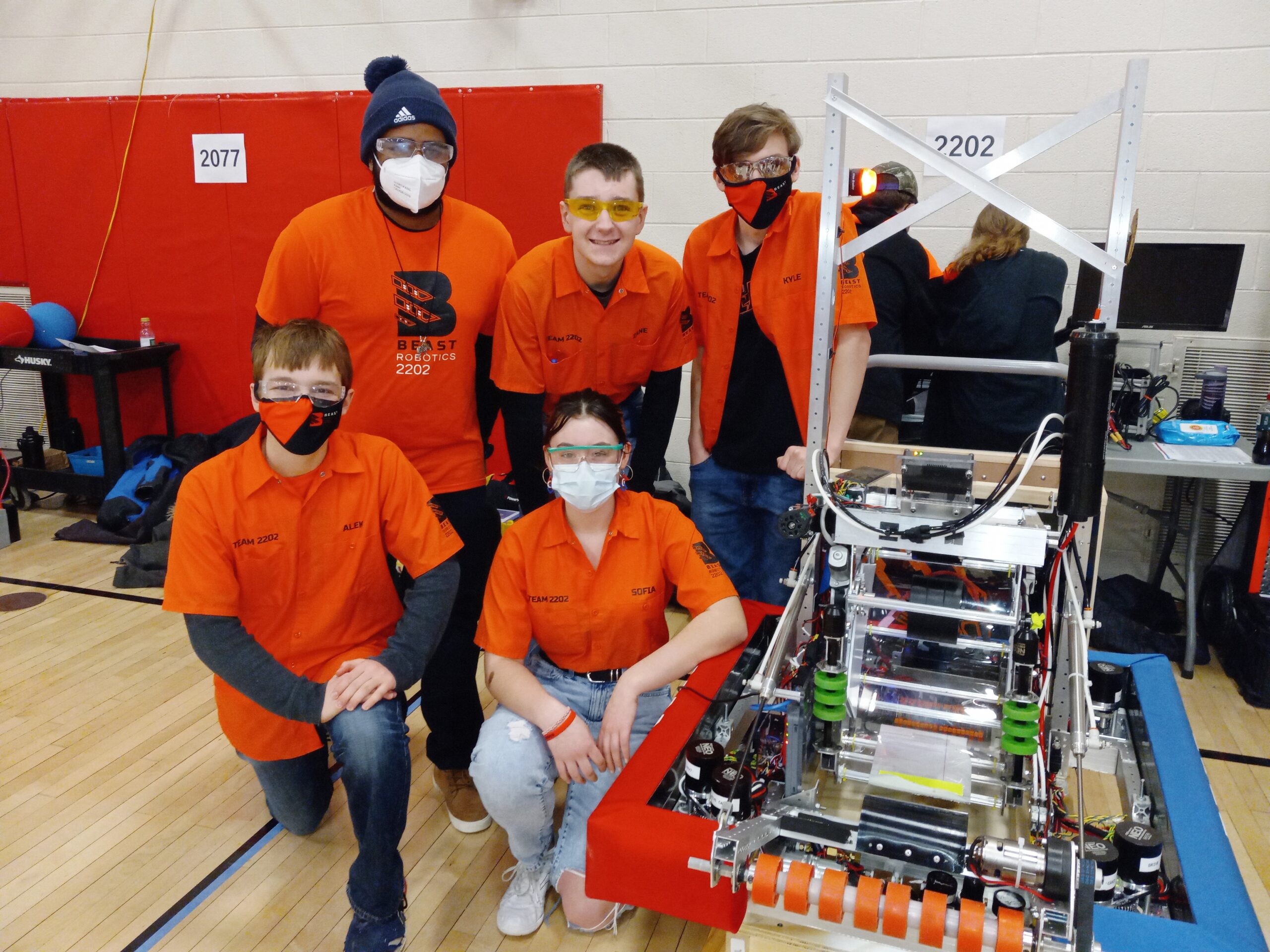

The Sussex Scrimmage on Sunday once again provided us with a great opportunity to test our robot before the official FIRST Robotics Competition events begin. This was the 22nd annual scrimmage hosted by FRC Team 537, Charger Robotics. A big shout out to them for the hard work they put into this well-run event! Twenty-five FRC teams participated in this year’s scrimmage. We were able to meet with other regional teams and check out their robots, share ideas with them and troubleshoot. Plus, it gave new members a chance to see how the competitions work logistically.

Although we did not test traversing the hangar, it was interesting to see some of the strategies other teams were using. By our count, there was only one robot able to successfully traverse the bars. It’s quite a challenge to lift and move the robot — most of the robots weigh over 125 pounds. Based on what we saw at the scrimmage, we’re excited about the design of our climbing arms. Our design has extendable arms that can also rotate. The two arms reach up and hook on a bar. Then they retract, pulling the robot into the air. The arms rotate, pivoting the robot and allowing a second set of fixed hooks to grab the bar. Then, the original, extendable arm hooks are free to move on and grab the next higher bar, allowing the robot to traverse the hangar bars.

Our intake system features several feeder wheels. The robot’s feeder wheels spin to pull the Cargo into the indexer. We are planning to improve the intake to minimize the probability of Cargo coming loose. Thanks to the fast swerve drive system on the chassis, we were able to move around quickly and easily intake two Cargo pieces into the indexer.

Once the robot collected two Cargo pieces, we were able to move to a good location on the field to aim for the Upper Hub. We were very excited about how well our pneumatics worked to set the robot’s shooter angle. Our drive team has a driver to move the robot and an operator to shoot the Cargo into the Hub. The software for driving the robot and manually shooting the Cargo worked well. The programming team has plans to improve the autonomous code, automate shooting, and fix some of the robot drive modes.

Our drive team consists of five people: driver, operator, technician, human player, and coach. The driver uses controllers with precision joystick extensions made by an alumnus. This feature provides more accurate turning and speed control, allowing our robot to really zip around the field. The drive team is currently training interested team members, and they were able to work with the robot in a competition-environment as well. This was a great experience for them.

We have about a month left until Wisconsin Regional. We need to attach the climbing arms to the robot and finish programming them. The software team is also developing the code for the autonomous portion of the challenge.

Strategy Team Update

The Strategy Team has created an app which is used to gather data about other robots during competition. By knowing this information, the team can determine our best strategy. The students work together to make sure the app and the data gathered from it are as accurate as possible. This allows the Drive Team to know what to expect and react accordingly in future matches. The Strategy Team goes from knowing nothing about other teams’ robots to having complete profiles on every single robot at a competition, including their accuracy, any malfunctions, and an overall rating.

Sponsor Visit

Thank you to Eric Lalor from Boyle Fredrickson for visiting our shop! Boyle Fredrickson is one of our long standing sponsors. They are Wisconsin’s largest intellectual property law firm. Mr. Lalor chatted with the team about how IP law protects the rights of creators and inventors. FIRST Robotics encourages students to tinker, innovate and invent. It was interesting to hear how IP law helps support the same creative thinking that FIRST Robotics encourages.

Mark Your Calendars

Mar 23-26: Wisconsin Regional (Milwaukee)

Apr 6-Apr 9: Minnesota 10,000 Lakes Regional (Minneapolis)